It’s almost impossible to imagine trail riding on a bike without a dropper post. They’ve become almost as ubiquitous as suspension forks, yet their wide appeal wasn’t fully realised until really recently in mountain biking’s history.

To riders who grew up in the modern dropper-post era, it might be surprising to learn that an external, seat-height-locating spring, called Hite Rite, was on the market even before RockShox launched its revolutionary RS-1 — the fork that won the very first UCI Mountain Bike World Championship back in 1990. Other models followed, but it was the introduction of the first RockShox Reverb, in 2010, that started the trend toward acceptance of the dropper post as an essential mountain bike component.

RockShox used its knowledge of suspension design to provide Reverb with real adjustability, and to fulfil the requests of riders looking for better on-trail performance than anything that was available at the time. But those were still the early days, the Wild West, and, despite its sophisticated nature, there were really no standards to which dropper posts were held. Testing for durability and reliability was still in its infancy, and yet dropper posts are more complex in most regards than other suspension products — and are typically asked to do and withstand more than them.

But mountain bike frame design continued to move forward at a relentless pace — and with it came a demand from riders for Stealth cable-routing, longer-travel options and products that can stand up to more hard use.

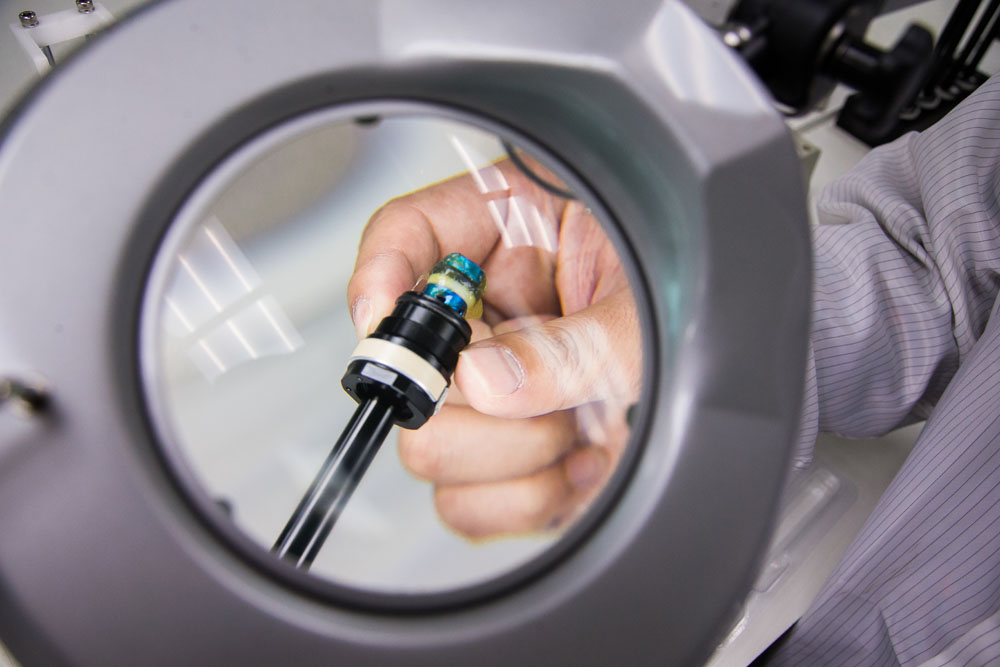

Like with its high-performance suspension products, RockShox builds the Reverb in a clean room. For the typical mountain biker, who has probably done a bit of trailside engineering, maybe overhauled a fork or two in the garage, and most definitely spent hours cleaning gunk from every part of a bike, the idea of people wearing hospital gowns while assembling products intended for muddy, loamy, dusty environments might not make sense. But the truth is that to ensure best-possible performance and longevity in the dirt, variables in the assembly process need to be eliminated. It’s a painstaking process that starts with cleanliness.

Each individual part needed to assemble a Reverb, whether manufactured by an outside supplier or whether it is made in one of SRAM’s factory facilities, is cleaned and packaged prior to it arriving for assembly. All of the parts then undergo inspection and a further cleaning process before being moved to an intermediate room, which is directly connected to the clean room. All parts are stored in bags and on trays until ready for final assembly.

Entering the Reverb clean room as a human is similarly meticulous. Perhaps it goes without saying, but the clean room is restricted to assembly operators and a select few others. Before going in to work, those with authorized access enter a staging room, change into shoes that have not been used outside the clean room, and then put on a lab coat and hat.

Inside, temperature and airflow are carefully controlled. Not only is properly maintained temperature of the parts, assembly machines and fixtures important to alleviate assembly variables, but the human brain also makes fewer mistakes when ambient temperature is kept at a cooler level than what most people find perfectly comfortable.

The Reverb assembly process is the adage “measure twice, cut once” taken to extremes. Every movement of a part, hand, tool or machine has been carefully engineered to ensure repeatability and eliminate errors. And it is not uncommon to see a SRAM engineer working on the assembly line, ensuring that a build process, which worked perfectly on prototypes a few months ago, still works as expected when 500 Reverbs roll off the line ever day.

When the assembly process is completed, the new, unpackaged Reverb exits the clean room through a negative airflow passageway. Once outside, it is packaged according to its final destination — bicycle manufacturer or retailer — and sent to fulfil its duty of getting dirty.

After six years of driving the dropper-post market, RockShox is now introducing a new, next-generation Reverb. Though it sports similar styling, the new Reverb has been reengineered to allow travel lengths between 100 and 170 millimeters and faster return speeds, as well as to increase bushing overlap, which results in smoother operation and greater fore-aft stiffness. Though the new Reverb was redesigned to increase performance, it also addresses dropper-post reliability issues and makes regular service easier.

Imagine trail riding, as it existed without dropper posts. RockShox wasn’t the first company to make a dropper post, and it surely won’t be the last, but the Reverb is unquestionably the one that gave dropper posts universal acceptance, and pushed the boundaries of performance. The new Reverb is now charged with raising the bar on the next generation of dropper posts.