Wil takes us through his new custom Tor hardtail

Back in 2019 I paid a visit to Tor Bikes in Beechworth. A modest one-man operation headed up by mechanical engineer Shane Flint, Tor Bikes specialises in producing custom handmade steel hardtails, gravel and road bikes, and even full suspension frames. While some are TIG welded, the majority are fillet-brazed, with an enormous amount of man-hours poured into each one.

During my time in the workshop I was immediately impressed by Shane’s attention to detail, craftsmanship and practical leanings. Many custom framebuilders rely on slick marketing and social media to sell the story behind their brand, but Shane prefers to let his frames do the talking. With a simple website, low-key graphics and a distinct lack of marketing gumpf, the no-nonsense approach appealed to me.

The Beechworth Connection

Shane and I have remained in contact since, and we often catch up for a ride and a beer whenever I’m visiting Beechworth. The two of us spend most of our rides geeking out on new bike tech, geometry and suspension designs, and I’m always keen to hear about what Shane has got going on in the workshop and the problems he’s attempting to solve at the time.

On a group ride a few months back, Shane and I began a lighthearted discussion about custom bikes. He’d recently finished building a pinion-equipped hardcore hardtail for the owner of Bridge Road Brewery, Ben Kraus, and the process had required a lot of bespoke details to bring it all together.

I’d never considered myself to be the sort of person who would buy a custom bike, but I could always see the value in having something purpose-built. I was also drawn to the idea of supporting a small business and having something handmade locally rather than mass-produced overseas. The itch was growing.

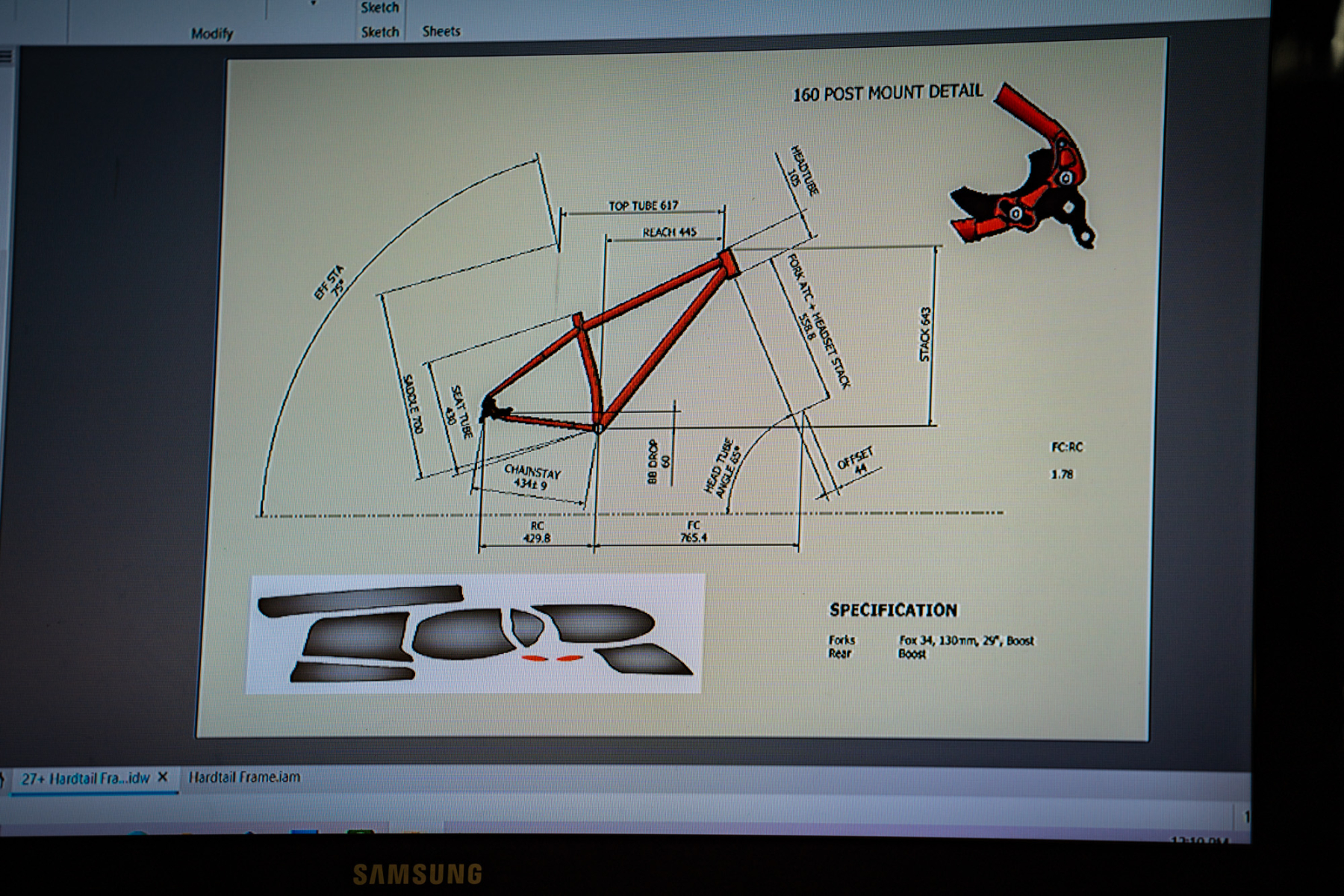

Over the next few months, that lighthearted discussion evolved into a long chain of emails. Soon we were discussing detailed geometry and frame specs. Shane presented some ideas, produced several CAD drawings, and we knuckled down on exactly what this bike was going to look like. Before I knew it, I laid down a deposit and frame tubes were ordered. We were really doing this.

The Idea

Now I’ll point out here that I’m definitely not a hardtail-only kind of guy. However, I have ridden a lot of them over the years. I tested a heap of them while living in the UK working for Singletrack Magazine, where I grew to appreciate their simplicity, ease of maintenance, and surprising capability when paired to modern geometry and components. I learned a lot during that time, and even had the opportunity to build my own sketchy hardtail out of bamboo.

There have been less hardtails in my life since returning to Australia, though the quantity was replaced with quality thanks to time spent on the Curve DownRock and the Cotic BFeMAX. I’ve also had the opportunity to build up a rather lovely Specialized Chisel, as well as testing some scary-fast bikes like the Canyon Exceed and the Cannondale Scalpel HT.

With that experience up my sleeve, I’ve developed a good idea of what I would want out of my own personal hardtail. However, being the Tech Editor at Flow, I already have plenty of test bikes to keep me busy throughout the year. As such, any new bike that would be entering the shed would need to have purpose to justify its existence. Merely being lovely to look at would not suffice. This bike would need to be versatile, practical, and ready to perform its duty as a rolling and evolving test rig.

What kind of bike is the Tor Mullock?

The custom bike I decided on is a 29er trail hardtail that’s designed to accommodate a 120-140mm travel fork.

This will allow me to build it up as a speedy XC bike with a RockShox SID or Fox 34 SC, along with lightweight wheels and fast-rolling 2.3in tyres. Alternatively I can throw on a RockShox Pike or Fox 34, burlier wheels and chunky 2.6in tyres for more technical trail riding.

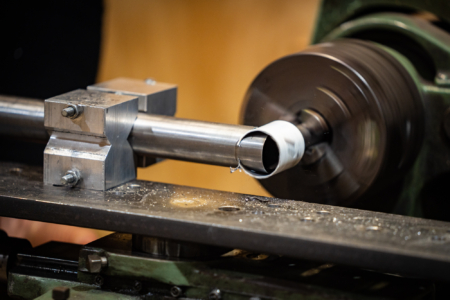

The frame is predominantly constructed from Colombus Zona tubing. The seat tube and chainstays are the exception, having been hand-bent in Shane’s workshop using 4130 chromoly tubes.

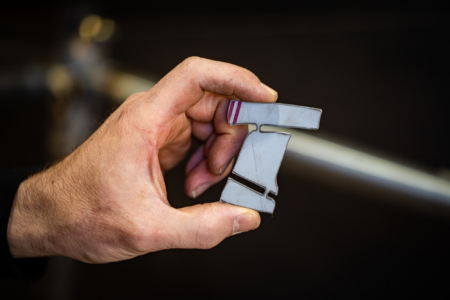

Paragon Machine Works supplied the 44mm headtube, 73mm threaded BB shell and adjustable dropouts. The pivoting dropouts provide up to 18mm of adjustment to the rear centre length, which is useful for fine-tuning the handling while also offering singlespeed compatibility.

Because I wanted a compact rear end and clearance for a 29×2.6in tyre, Shane had to get a little creative. He ended up sourcing custom chainstay yokes from Cobra Framebuilding in the US. These not only facilitate the big volume rubber, but also allow for a standard 52mm Boost chainline because I prefer a narrower Q-factor.

The whole frame has been fillet-brazed in the Tor Bikes workshop in Beechworth. Shane has hand-filed all of the joins to leave a super smooth transition between each tube. It may not offer any performance advantages over TIG-welding, but gosh that fillet-brazed finish is lovely!

Geometry

Easily the most time-consuming phase of the design process was settling on the geometry for my custom hardtail. While I do have hardtail history, I have a lot more experience testing full suspension bikes. Translating full suspension geometry over to a hardtail is quite tricky however, so it took me a while to settle on the numbers I thought would work best for me.

For those interested, here’s what I ended up going with to suit my 175cm height;

- Head tube angle: 65°

- Effective seat tube angle: 75° (measured at correct saddle height)

- Reach: 445mm

- BB drop: 60mm

- Rear Centre length: 420-438mm

Paint My Ride

After agonising over the frame specs and geometry for what seemed like an eternity, the paint job was honestly the last thing on my mind. That’s not helped by there being an infinite range of possibilities, with Shane offering powdercoating, painting and Cerakote options for finishing his frames.

Sensing a fresh round of indecisiveness, Shane suggested for this project we commission Velo Craft to paint the frame.

Based in Melbourne, Velo Craft is a speciality paint shop. In addition to doing custom one-off paint jobs, Velo Craft finishes all of Bastion’s frames, while also doing some warranty work for Specialized. Though most of the bikes passing through are of the road and gravel variety, Steve Gardner, the owner and lead painter, is originally a mountain biker and was keen to be involved.

I figured I wanted a single colour, a dark tone and perhaps a metallic finish. Steve rattled off some suggestions, and sent through some photos to show a British Racing Green colour he’d done recently. After giving a virtual thumbs up, I arrived at the Velo Craft workshop in Boronia two weeks later to pick up the frame.

I’m honestly stoked with the finish, which is quite dark in the shade, but sparkles and dances in the light. The thick layer of paint is remarkably smooth, accentuating the seamless fillet-brazed joins. The polished 3D head tube badge is a great touch.

Where does the name come from?

As you may know already from our Tor Bikes feature, the brand name comes from Shane’s time living in the UK. Over there, the word ‘tor’ refers a large rocky outcrop. The name is also relevant to Beechworth as the place is covered in rocky outcrops, as anyone who’s visited the granite-filled Beechworth MTB Park will attest to.

The Tor model names follow a similar geological theme with the ‘Erode’ full suspension bike, and the ‘Abrade’ hardcore hardtail. While my bike was originally based off the Abrade, it went sufficiently off-script that I figured it was worthy of its own unique name.

Now I don’t make a habit of naming my bikes, but this did present a cool opportunity to come up with something to tie in the Bendigo-Beechworth connection. While we don’t have many tors around Bendigo, the landscape is littered with mining leftovers from the 1800s gold rush. In addition to the old poppetheads and mine sites, all around town you’ll spot large piles of rubble left over from digging sites that are referred to as ‘mullock heaps’. Put simply, a mullock is essentially a man-made tor.

In speaking with Shane about my idea, it turned out that ‘Mullock’ was actually one of the options in his shortlist when he was coming up with the original brand name. Acknowledging this coincidence, and the shared gold mining history between Beechworth and Bendigo, the Tor Mullock seemed like the perfect fit for my new bike.

The Build

The idea behind the Tor Mullock was to develop a reliable and familiar platform for reviewing forks, wheels, tyres brakes and various components. A hardtail is ideal for this purpose, as it provides undiluted trail feedback that makes it easier to feel the differences between two otherwise very similar parts.

To get it rolling, I’ve initially built it up with a combination of new parts that I’m in the process of reviewing, as well as some older parts that we’ve either finished testing or just had laying around in the workshop.

Notable highlights include the excellent Fox 34 GRIP2 fork, the trick CNC machined Hope Tech 4 brakes, and the compliant Stan’s NoTubes Arch MK4 wheelset with its fast-engaging Project 321 freehub mechanism.

Tor Mullock Specifications

- Frame | Tor Custom Steel, Fillet Brazed, Adjustable Dropouts

- Headset | Wolf Tooth Components Premium ZS44/EC44

- Fork | Fox 34, Factory Series, GRIP2 Damper, 44mm Offset, 130mm Travel

- Wheels | Stan’s NoTubes Arch MK4, Alloy Rims, 28mm Inner Width

- Tyres | Continental Xynotal Trail, 2.4in Front & Rear

- Inserts | CushCore Pro (Rear)

- Drivetrain | Shimano SLX 1×12 w/32T Race Face Era Crankset & 10-51T SLX Cassette

- Brakes | Hope Tech 4 E4 w/180mm Rotors

- Bar | Truvativ Atmos 7K Alloy, 20mm Rise, 760mm Width

- Stem | Truvativ Atmos 7K Alloy, 50mm Length

- Grips | Ergon GFR1

- Seatpost | Fox Transfer Factory Series, 31.6mm Diameter, 150mm Travel

- Saddle | Ergon SM Pro, S/M

- Frame Weight | 3.02kg

- Complete Bike Weight | 13.43kg

What’s next?

While the initial build is fairly representative of what I would want out of the bike, though there are some things that I’ll be experimenting with in future.

Given how much clearance there is through the rear of the frame, I’m keen to try out some 2.6in wide tyres to add further compliance and grip. And while the cockpit feels pretty comfortable already, I’ll spend some time dialling in the position to get it just-so.

I decided to try out a set of 165mm cranks on this bike rather than the usual 170mm length that I’m used to riding. I’m curious as to how the shorter arms will feel, though given how low the BB is on this bike, at the very least the increased pedal clearance will be a positive.

Of course there’s the option to change the rear centre length from short and nimble to long and stable, and I’ll also be able to experiment with different travel forks. Furthermore, there’s the option to run an angle-adjust headset should I wish to go down that rabbit hole. I’ve currently got lovely Wolf Tooth Premium headset in there, though the same brand does offer a GeoShift headset for tweaking the head angle.

There are a couple of minor tweaks I need to make in the meantime. I’ll add some frame stickers, a chainstay protector, bottle cage and some nicer headset spacers. All the cables and brake hoses have been left on the long side to begin with, but I’ll be trimming those down shortly to neaten things up.

Otherwise all that’s left to do is to ride the thing. Well, as soon as I stop gawking at that lovely paint job!