At the end of October, Canyon revealed its KIS steering stabiliser. Designed in collaboration with Liteville and Syntace, founded by Jo Klieber. A widget anchors inside the top tube and uses steel springs and a high-stretch polymer cord that connects to a specially designed cam that clamps onto the fork steerer.

At rest, it holds the front wheel centred. When you turn the bars, the springs stretch and apply counterforce. It’s a similar idea to the steering dampers found on some motorbikes — and the Cane Creek Viscoset and Hopey Steering Dampers from the early 2000s — the concept is to control wheel flop and keep steering more neutral.

It’s an interesting concept that has been tried before, however this iteration is unique, and with the speed at which Canyon has rushed to push this technology into production, it appears the German brand believes it’s onto something.

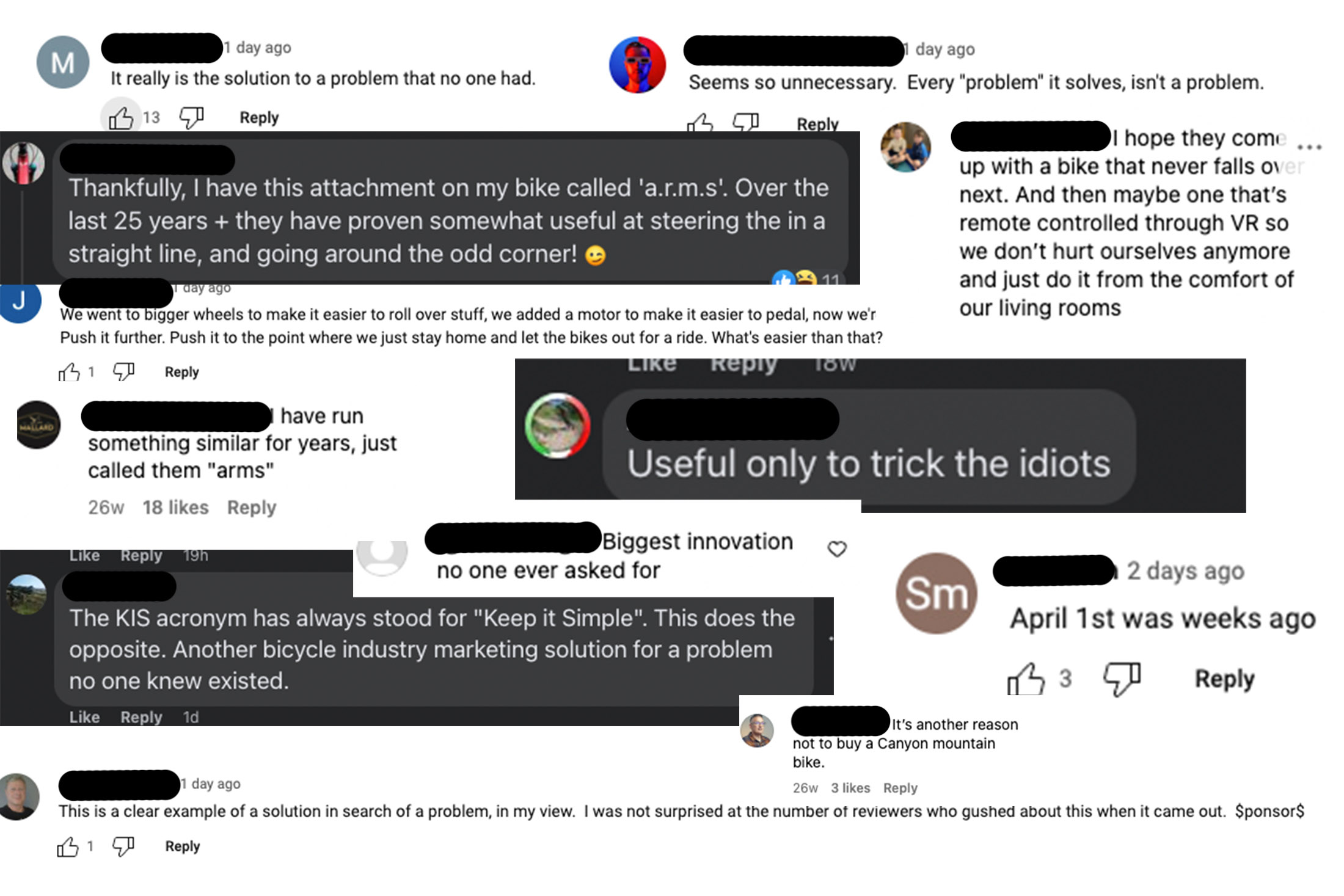

But in typical fashion, the comments section of this piece and our subsequent review was alight with folks criticising the technology before they’ve ever laid their hands on it. This happens all the time, and it’s not totally unwarranted as the bike industry has served up some stinkers that were pitched as THE next big thing — unified rear triangle and plus tyres to name a few.

However, there are just as many bits of tech that people had written off from the beginning that have now become an integral part of their life on the bike. We’ve all heard the worn-out 29in wheel, tubeless tyre, and disc brake argument before, so here are some more recent examples of technology that got the comment section humming with negativity that has turned out to be great.

Clutched Rear Derailleur | Dropped chains and noise be gone!

Long before SRAM officially declared the front derailleur dead — for MTB at least — in 2014, 1x drivetrains weren’t initially an easy sell. But, in 2022, I don’t think you’ll find anyone who will disagree that attaching the front derailleur to a cinder block and dropping it off the Harbour Bridge was the right call. But, back in 2011, with SRAM and Shimano still figuring out how 1x would work, many thunderous voices questioned the need for clutched rear derailleurs.

One of the first reviews of this new tech was published on BikeRadar, one of the world’s largest tech and review sites (and this writer’s former employer) after Shimano introduced its Shadow+ rear derailleur read, “The usefulness of this technology will definitely vary from rider to rider. It’s unlikely to appeal to cross-country racers, and it might not even be for every trail rider, as it’s slightly heavier and slightly more expensive than the standard XTR M980 rear mech.”

This same review went on to complain about the heavy shifting action. It also touts the superiority of a chain guide for chain retention, musing that the clutch mechanism would be best used for folks running a triple chainring because guides for these cranks were rarer than hen’s teeth.

But it wasn’t just cycling journalists with large platforms. Dive into the comments section of any article from the era, and you’ll find folks proudly proclaiming they won’t be upgrading to a clutched derailleur because it’s solving a problem that doesn’t exist.

Of course, hindsight is 20/20, and anyone who’s pinballed down a rock garden over the last decade and not dropped a chain can attest to the utility of the clutch preventing the chain from swinging around like a pair of nunchucks.

DUB | One spindle to rule them all

I’d like to preface this section by saying clearly that the 54nm torque spec on a DUB crank is ridiculous. I should not need to own a 24in breaker bar and need to enlist the front row of my local rugby league club to break loose a crank bolt.

Small complaints aside, DUB as a standard is brilliant. Navigating bottom bracket and crank compatibility can be a bit like trying to win the milk bottle game at the carnival. Do you want one spindle size to fit across all major BB shell sizes? Yep. Hitting a range of price points, with identical bearing placement for each bottom bracket? Sign me up.

With its 28.99 spindle, SRAM says its goal was to achieve a single design that would fit into any frame regardless of the BB shell standard chosen by a bike manufacturer. And when it comes to new standards, this is a pretty innocuous change. It’s not like it made your frame, fork and wheels obsolete like Boost did — more on this later.

When SRAM announced this 1.01mm difference in spindle diameter, you’d swear they declared that cassettes and derailleurs would now be mounted at the cranks. Yes, new standards are annoying, but in this case, it’s genuinely a better option and not just because it simplifies marrying up key components on your bike.

Everyone wanted 30mm spindle cranks because they are lighter. The trouble is they also seriously lacked the durability of the 24mm GXP system — the stock BBs that came on a lot of bikes lasted about as long as a cardboard box in a rainstorm.

The BB92 standard is by far the most common across modern MTB frames, and having to accommodate a 30mm spindle doesn’t leave room for much sealing in a bearing race. One millimetre may not sound like much, but it may as well be a mile in terms of water and dust ingress. SRAM didn’t invent BB92 — that was another ‘S’ brand — and it proved to be a terrible fit with the larger axel.

SRAM makes lofty marketing claims about how long these new bearings will last, and we’re not going to repeat them here. Anecdotally, I have done more bike cleaning and gone through more chains and cassettes than ever in the last year or so, thanks to logging more damp, wet and gritty days on the bike. With that in mind, my BB has had precisely zero attention, the bearings spin freely, and there is no play or crunchiness. It’s far from a scientific study, but it’s a win in my book.

Tyre Inserts | Less like a tube and more like a pool noodle, but better

When Schwalbe announced the ProCore, tyre within a tyre, many around the bike industry snickered from their high horse, proclaiming that we gave up tubes many moons ago and haven’t had a pinch flat since.

You can still find Procore floating around in the bowels of online bike shops, however they are more or less gone with time. Now instead of a tyre within a tyre, everyone from XC whippets to DH dynamos are running some definition of a foam tyre insert.

The idea is exactly the same. It’s something to be run inside that puts a bit of padding between the casing and the rim, serving as a bottom-out bumper to prevent damage at either end.

Beyond the classic, “this is creating a solution for a problem people don’t have” critiques of the Procore, many were unhappy with the ~200g per end weight penalty, added complexity, special valves and price.

For reference, Cushcore weighs ~150g per end, can be extraordinarily difficult to install and also requires special valves — it’s cheaper though!

Metric Shock Sizing | A standard that actually standardised something

Announcing a new industry-wide standard on April Fool’s day, was probably not the best idea — or was it genius — but that’s exactly what happened in 2016 when RockShox, Cane Creek, DVO, Manitou, SR Suntour and X-Fusion advised they would be swapping exclusively to metric sizing. Fox stated (and is still) producing both Imperial and metric-based shocks dependent on market demands. But the significant change here wasn’t the swap from inches to millimetres.

The new metric sizing system was the suspension manufacturers saying, “here are the eye-to-eye and stroke lengths we’re offering, please design your frames and suspension layouts around them.”

Prior to this, brands would design a frame, call up RockShox, DVO or Fox and say, “we need this size shock.” And if that brand was willing to make a large enough order, the suspension brands would make it — the same thing happened for mounting hardware.

As you can imagine, this spiralled out of control and led to an excess of proprietary shock and hardware sizes — to the tune of 80+ mounting hardware dimensions. It was a nightmare for the suspension manufacturers, and worse for the shops that had to service them.

The standardisation of the sizing would also allow the suspension brands to design shocks based on creating the best possible performance, rather than trying to fit a square peg into a round hole.

Once folks realised this swap of rear suspension standard, social media erupted with the force of Mount St Helens. And it was not totally unfounded, with many folks worried they wouldn’t be able to get parts, or replacements if they blew a shock. Eventually, this will be the case, but the spares haven’t dried up for the time being.

Boost Hub Spacing | Making wheels feel less like spaghetti noodles since 2015

Remember riding 29in wheels circa 2015? The flexy unwieldy wagon wheels felt like trying to build a suspension bridge using greek yoghurt. Yes, your fancy non-boost ENVE wheels of the day could still rattle your teeth loose with the bike on edge, while tracking in a straight line, but in all honesty, they probably don’t need spokes to achieve that. But anything that wasn’t made of exotic materials and moulded in Ogden, Utah, was akin to overcooked spaghetti.

Then Trek and SRAM introduced the Boost hub spacing. First debuted aboard the Remedy in 2015, this new standard saw the rear end hub flange spacing pushed out from 142mm to 148mm (or 3mm on each side), and the front end grew from 100mm to 110mm (or 5mm each side.)

When the industry at large swapped from 135mm to 142mm, mountain bikers everywhere rejoiced because, for 30-bucks, you could get a set of end caps that took up the extra space. The trouble was we’d allowed ourselves all of this additional real estate to make a better wheel and instead decided not to take advantage of it. And so, with all the disdain that mountain bikers hold for new standards, the next one is a self-inflicted wound. But I digress.

Widening the hub flanges used this real estate to increase the spoke bracing angle, meaning a sub-$500 wheel could track properly through a corner.

I’m going to speculate here for a moment, but thanks to the hub and spokes actually being able to keep the rim in plain when it was loaded with energy is likely the innovation that has brought about carbon wheels that don’t feel like they’re made from bent 2x4s.

The knock-on effect of moving the hub flanges out is that it also pushed everything outside the hub flanges out. With the extra 3 mm on each side, it also pushed the chain line out by the same margin. According to Trek, it went with 148mm in the beginning because it wouldn’t affect the Q-factor. But with more wiggle room inside of the chain line, it also meant that there was extra space for wider tyres and larger chainrings too.

Boost came about just before the plus tyre revolution was launched over the edge of bike industry trends that were good in theory but didn’t quite work out.

This is only a short list of innovations from the bike industry that a large portion of folks initially turned their nose up at, however, we bet those exact same people wouldn’t go back given the option. Canyon’s KIS is the latest to inspire folks to warm up their typing fingers before they’ve seen a product in real life, and you can bet there will be plenty more.

Have we missed any big ones? Let us know in the comments.